ON SITE / LABORATORY

- -

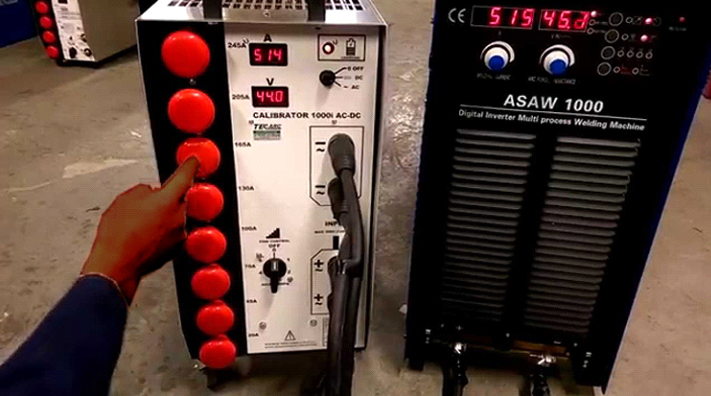

Gallery

Description

Welding machine calibration is the process of adjusting and verifying a welding machine to ensure it meets the required standards and produces consistent, accurate results. It is an important component of quality control and can help prevent poor weld quality that can lead to product defects, safety hazards and financial losses.

It is important to follow the manufacturer's calibration and maintenance recommendations, as they may vary by machine and application. Standard-grade equipment should be calibrated every 12 months, while precision-grade equipment should be calibrated every 6 months. However, depending on the use of the machine, the environment in which it is used, or whether it has been repaired, it may need to be calibrated more frequently. Establish a regular calibration and maintenance schedule to keep your welding machine in top condition.

07-8610021, 07-8614690

07-8610021, 07-8614690